SMT STENCILS

High-quality laser cut and chemically etched SMT stencils that you can rely on.

HIGHLIGHTS

We proudly use the LPKF SL25 stencil laser system to cut foils for our solderpaste stencils. It has superior positional accuracy and cutting tolerances. We only use Datum PHD material for our stencils because of the material's superior laser cutting quality, 2% thickness tolerance as well as being more relaxed for chemical etching stepdown and relief areas. Datum FG (Fine Grain) is available on request. It has a 1 to 2 micron grain size that is well suited to complex, high density, multilayer (stepdown) stencils. It is a great alternative to more expensive electroformed nickel.

- CAD/CAM specialists with over 30 years of aperture editing experience

- Full service chemical etch department in-house

- 24-48 turn times

- 2 mil to 20+ mil thick foils

- For pre-process, we offer chemically etched step foils (dual and multilayer)

- Standard poly mesh, with stainless steel mesh available

- Popular frame sizes and types such as cast, tubular, space saver, and custom frames

- Foils for reusable frame systems and foil only stencils

- For post-process, we offer electro-polish, electro-polish and nickel plate, and electro-polish and Aculon NanoClear coating.

TESTIMONIAL

I have been in the Industry for 20 years and have worked with multiple Stencil Suppliers over the years. We have found a massive improvement with our quality on solder joints since working with Photo Design due to the excellent quality of their Laser cut stencils and the standard modifications that are done with us not having to worry as their wealth of knowledge on the best sizes and shapes for different devices.

FRAMED & FRAMELESS SMT STENCILS

Whether you are looking for the precision and durability of a framed SMT stencil or the convenience of a reusable frameless SMT stencil, we have the in-house capabilities and expertise to deliver on-time and on budget for you and your organization.

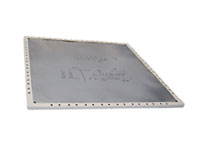

Framed SMT Stencils:

Framed SMT stencils are perfect for high volume production runs because of their durability and precision. The foil is permanently attached to the aluminum frame. Pick from a variety of popular frame sizes or we can build custom frames upon request.

Framed SMT stencils are perfect for high volume production runs because of their durability and precision. The foil is permanently attached to the aluminum frame. Pick from a variety of popular frame sizes or we can build custom frames upon request.

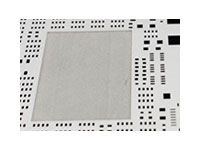

Frameless SMT Stencils:

Frameless laser cut stencils are used with reusable SMT stencil frames. Frameless SMT stencils are recommended for smaller prototype PCB assembly runs. They are convenient in their size to store and they cost less than Framed SMT stencils.

Frameless laser cut stencils are used with reusable SMT stencil frames. Frameless SMT stencils are recommended for smaller prototype PCB assembly runs. They are convenient in their size to store and they cost less than Framed SMT stencils.

PROTOTYPE SMT STENCILS (FOIL ONLY)

Prototype SMT Stencils:

Foil only prototype SMT stencils are recommended for replacing hand soldering prototype quantities of your PCBs. Available with or without side flaps, they help reduce assembly time for your prototype PCBs.

Foil only prototype SMT stencils are recommended for replacing hand soldering prototype quantities of your PCBs. Available with or without side flaps, they help reduce assembly time for your prototype PCBs.

STEP-UP/DOWN & RELIEF SMT STENCILS

Our full-service chemical etch department can help you design your SMT stencil step areas. We are a leading wholesaler of chemically etched high-performance SMT stencils for multiple large stencil houses around the globe.

Step-down/up SMT Stencils:

SMT stencils with a step-down area are for components that have a very fine pitch and require less volume than the rest of the stencil thickness.

SMT stencils with a step-up area are for components that require the extra volume of paste but the rest of the components do not.

SMT stencils with a step-down area are for components that have a very fine pitch and require less volume than the rest of the stencil thickness.

SMT stencils with a step-up area are for components that require the extra volume of paste but the rest of the components do not.

Relief SMT Stencils:

Step relief stencils are located on the bottom of the stencil to relieve areas that are protruding above the normal board area such as labels, protruding vias, and additive traces. This helps to provide better gasketing during the printing process.

Step relief stencils are located on the bottom of the stencil to relieve areas that are protruding above the normal board area such as labels, protruding vias, and additive traces. This helps to provide better gasketing during the printing process.

MINI/REWORK SMT STENCILS

Rework SMT Stencils:

Rework or Mini SMT stencils are typically used for reworking a specific component on the PCB, however, they can be used if your PCB is very simple and small. They are available with our without side flaps.

Rework or Mini SMT stencils are typically used for reworking a specific component on the PCB, however, they can be used if your PCB is very simple and small. They are available with our without side flaps.